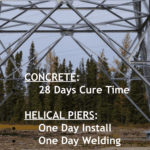

For Energy Renewables

Estimated 98.5% Smaller Carbon Footprint VS Concrete

Why Choose Helical Pier Foundations for Renewables?

Helical piers, also known as screw piles, helical piles, or helical anchors, are foundation systems widely used in renewable energy projects, particularly in the context of solar and wind energy. These piles are engineered to provide strong and reliable support for various structures, including battery energy storage systems (BESS), substations, solar panels, and wind turbines.

BESS Projects

Helical piers are an increasingly popular choice in battery energy storage systems due to their numerous advantages, including ease of installation, load-bearing capacity, and adaptability to various soil conditions. As the demand for energy storage systems continues to grow, helical piers offer a reliable foundation solution for these crucial infrastructure projects.

Substations

Helical piers offer excellent load-bearing capacity, ensuring the stability of the substation structure even in soft or unstable soil conditions. Installing helical piers generates less noise and vibration compared to other foundation techniques, making them suitable for projects near residential areas or locations with noise restrictions. High-side breakers, low-side breakers, static masts, dead-end structures, control buildings, transformers, and HV cabinets are some of the various structures that can be supported by helical pier foundations.

Solar Energy Projects

Helical piers are commonly used to support solar panel arrays. The piers are screwed into the ground, penetrating the soil until they reach a stable load-bearing layer. This creates a solid foundation for solar panels, ensuring stability and longevity. Helical piers are ideal for solar installations because they offer a quick and cost-effective foundation solution, even in challenging soil conditions. They can be easily installed with minimal environmental impact, making them suitable for both small-scale and large-scale solar farms.

Wind Energy Projects

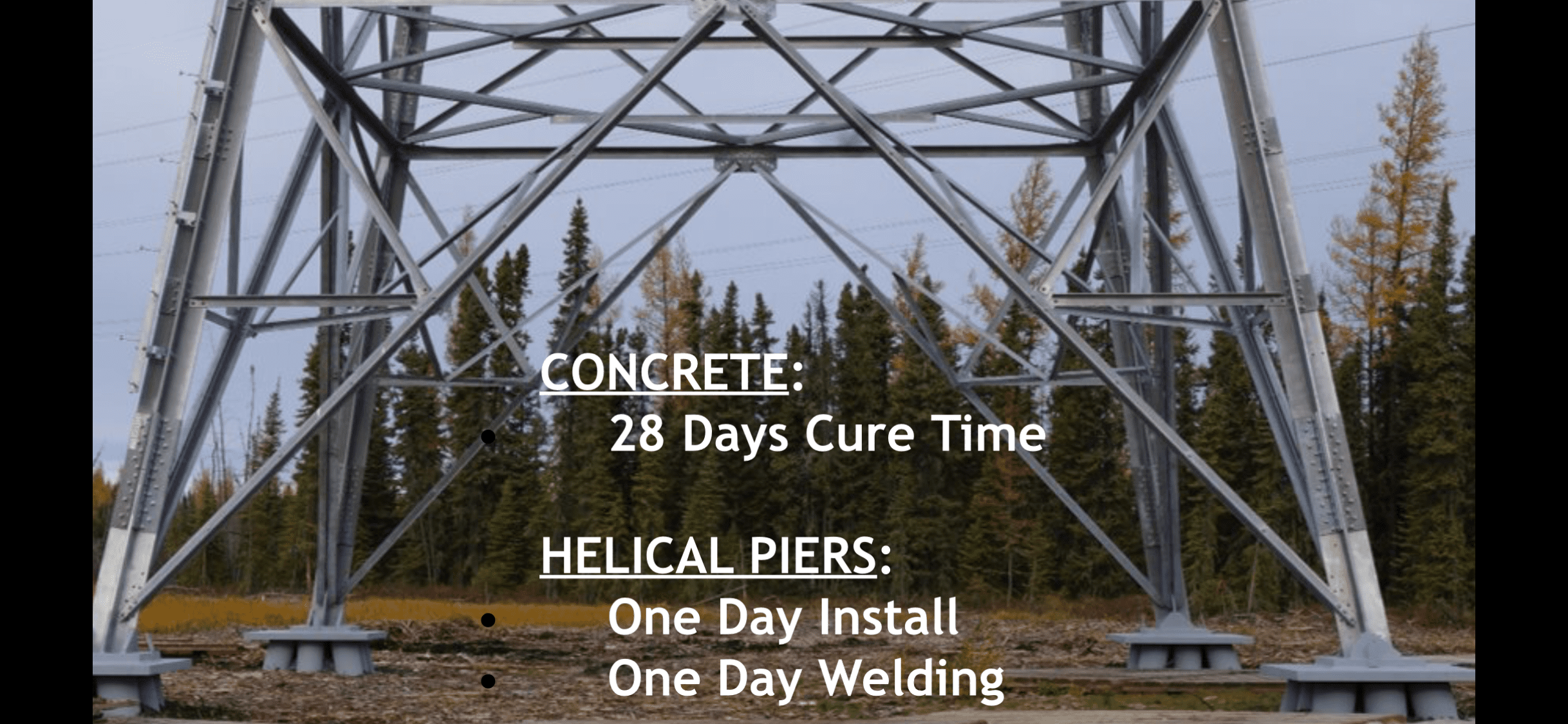

Helical piers are also utilized in wind energy projects, particularly for onshore wind turbines. The piers are used to anchor the turbine towers securely to the ground. The twisting action of the helical piers during installation compacts the surrounding soil, enhancing stability and load-bearing capacity. Helical pier foundations are favored in wind energy due to their ease of installation, minimal site disruption, and suitability for various terrains and soil types.

Oil & Gas

Helical piers are commonly used in the oil and gas industry for various applications. These specialized foundation elements consist of a steel shaft with helical plates (or helices) that resemble large screws. They are screwed into the ground to provide structural support and stability for various equipment and structures in oil and gas operations.

Energy Storage

We specialize in helical pier installations for energy storage systems, helping our clients enhance their energy infrastructure efficiently and cost-effectively.

History of Helical Piers

Helical piers, also known as helical piles, helical anchors, or screw piles, have a fascinating history that dates back several centuries. The concept of helical piers emerged from various engineering and construction practices around the world.

Mid-19th Century

Helical foundations can be traced back to the mid-19th century. Alexander Mitchell, an Irish civil engineer, is often credited with the development of the screw-pile foundation. In 1833, he patented a screw-pile lighthouse foundation design, which was used for constructing lighthouses and other structures in soft, marshy ground or underwater sites.

Early 20th Century

Throughout the 19th and early 20th centuries, screw piles became one of the most popular ways of constructing lighthouses, bridges, and piers in coastal regions, especially in places with poor soil conditions. These early helical piers were manually screwed into the ground using various methods, often with the help of human or animal labor.

1950s and 1960s

In the 1950s and 1960s, technological advancements led to the development of more efficient helical pier designs and installation methods. Engineers began using hydraulic machinery to install helical piers, making the process quicker and more reliable.

Helical piers started gaining traction in the civil engineering and construction industries during the late 20th century. Their applications expanded to include various types of structures such as buildings, bridges, communication towers, and transportation infrastructure.

Today

With advancements in materials science, manufacturing techniques, and engineering design, helical piers have become a versatile and widely used foundation solution. Today, helical piers are commonly made of steel and are designed to withstand specific load requirements based on the project’s needs. They offer several advantages over traditional foundation methods, such as faster installation, reduced site disruption, lower environmental impact, and the ability to bear heavy loads in various soil conditions. These benefits have contributed to their growing popularity in the construction industry.

Today, helical piers continue to find applications in both residential and commercial construction projects. They are often used for underpinning existing structures, supporting foundations in environmentally sensitive areas, and stabilizing structures in regions prone to seismic activity or soil subsidence.

2305 Ridge Road, Suite 202, Rockwall, TX 75087

(214) 556-8125